Description

Spool Performance fuel pumps for BMW models

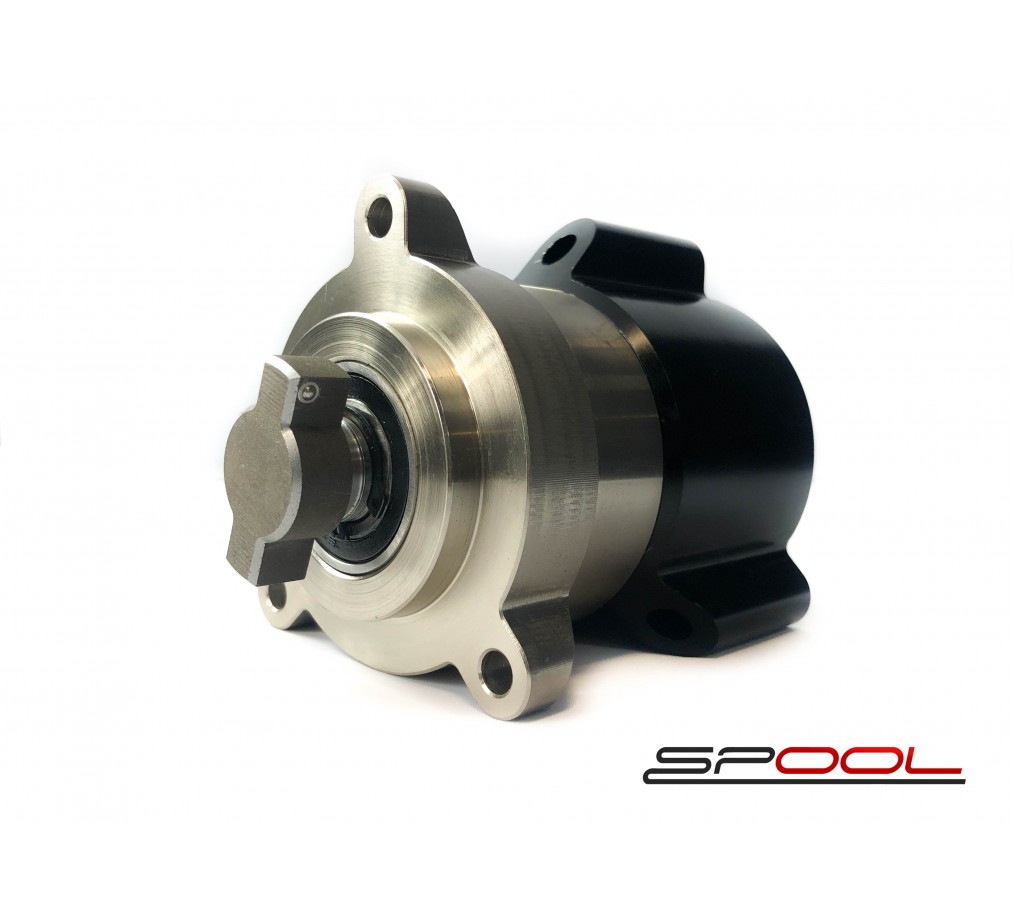

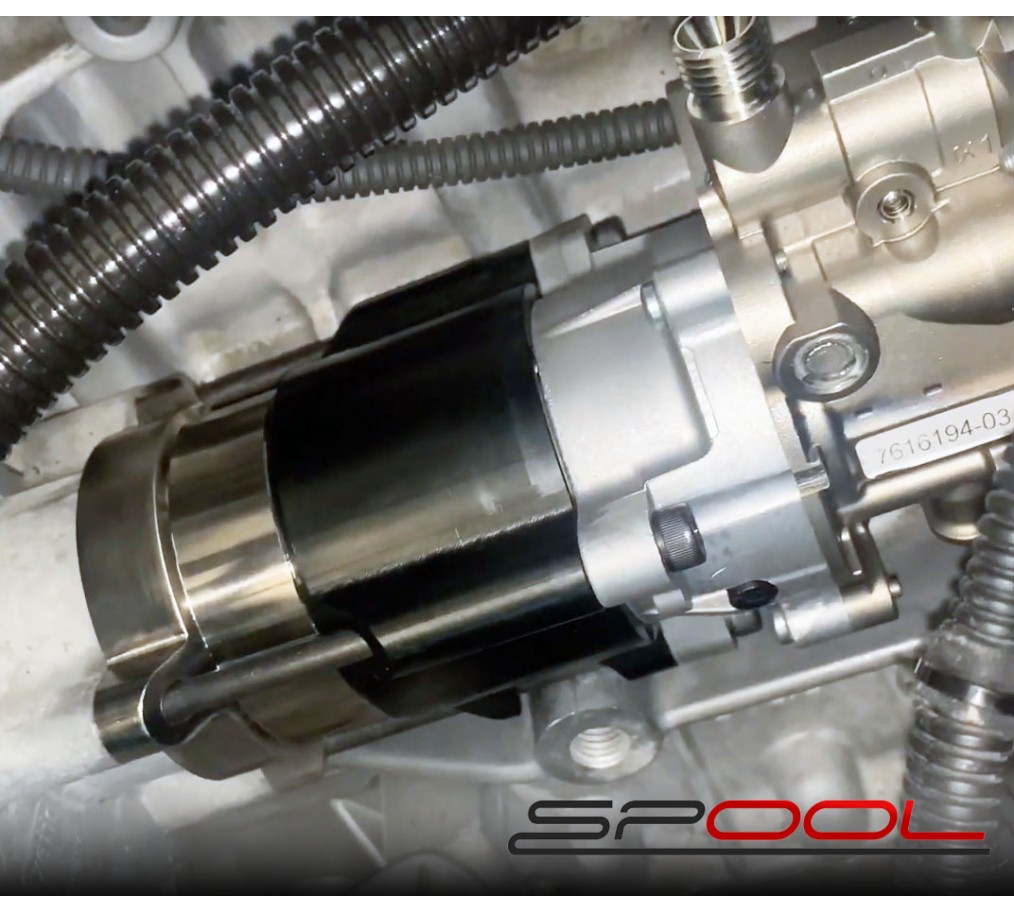

Spool HPFP Overdrive, Helix gear, BMW N54 / N55 engines (E6x E8x E9x)

BMW N54 and (early) N55 are known to have decently solid HPFP fuel pump, but as the stage of tuning rises, the capacity of Continental rotary pump will eventually become a problem. Fuel pressure crashes especially in low- to mid rpm range under high torque, leading to misfires, problems with AFR and obviously a compromised power output.

As high volume pumps are not available for these early models, only and most logical solution is to increase the revs on pump axle for more output.

Spool HELIX is basically a planetary gear, somewhat similar in it’s base idea as to what you can find inside an automatic gearbox. Spool configuration of the gears and their spatial fixturing allows an axial increase in shaft speed from the input to the output of the unit.

- Ready to install, all accessories and brackets included

- Helix gear increases the pump revolutions per cycle, offering significantly more output.

- Well tested setup, not compromising the longevity of stock HPFP

- Up to +850hp power levels!

Tip for high power builds

In case your looking for high output over +550whp, our recommendation is to remove the original fuel filter inside your BMW HPFP unit, and install a high flow In-line filter from Spool instead. Original filter becomes a restriction at higher output levels.

About N54 HPFP longevity

We all know that the continental Hpfps have been subject to failures and recalls in the past. Because of that, it has been a high priority for manufacturer to test it all thoroughly and investigate what is it that makes these fail for some. From investigating a number of failed units, two cases of failure were established as the most common.

The first mode is inlet metering valve actuation failure due to failures in actuation solenoid coil and second is the limp home mode bypass valve leaking. The limp home mode valve connects the low-pressure inlet to the high-pressure outlet of the pump and remains closed as long as there is a higher pressure on the high-pressure side. Purpose of this valve is to flow in the case of an hpfp failure.

It seems that in older units, this valve starts leaking from high pressure to the low-pressure side preventing the hpfp from being able to build full pressure in the rails. The valve relies on rubber elements to seal under normal operation and the problem might be in the material used in early productions, or the use of bad quality fuels.

In some cases a cracked bellows were found as well but this seemed to be that only one out of more than 20 failed pumps were affected by this. Oil of the high mileage units was analyzed and they showed very little metal content. Physical examination of the squash plate, springs and pistons proved that these elements are indeed designed to last and had very little wear.

Summary

To sum it up, most failurs on the hpfp unit are for reasons not related to the revolution speed of the pump.